- Sorting and valorisation of ordinary industrial waste, construction waste, wood, plastics and green waste

- Consolidation and valorisation of hazardous waste

- Processing and production of Solid Recovered Fuel (SRF)

- Decontamination and valorisation of End-of-Life Vehicles (ELVs) and End-of-Life Recreational Craft (ELRC)

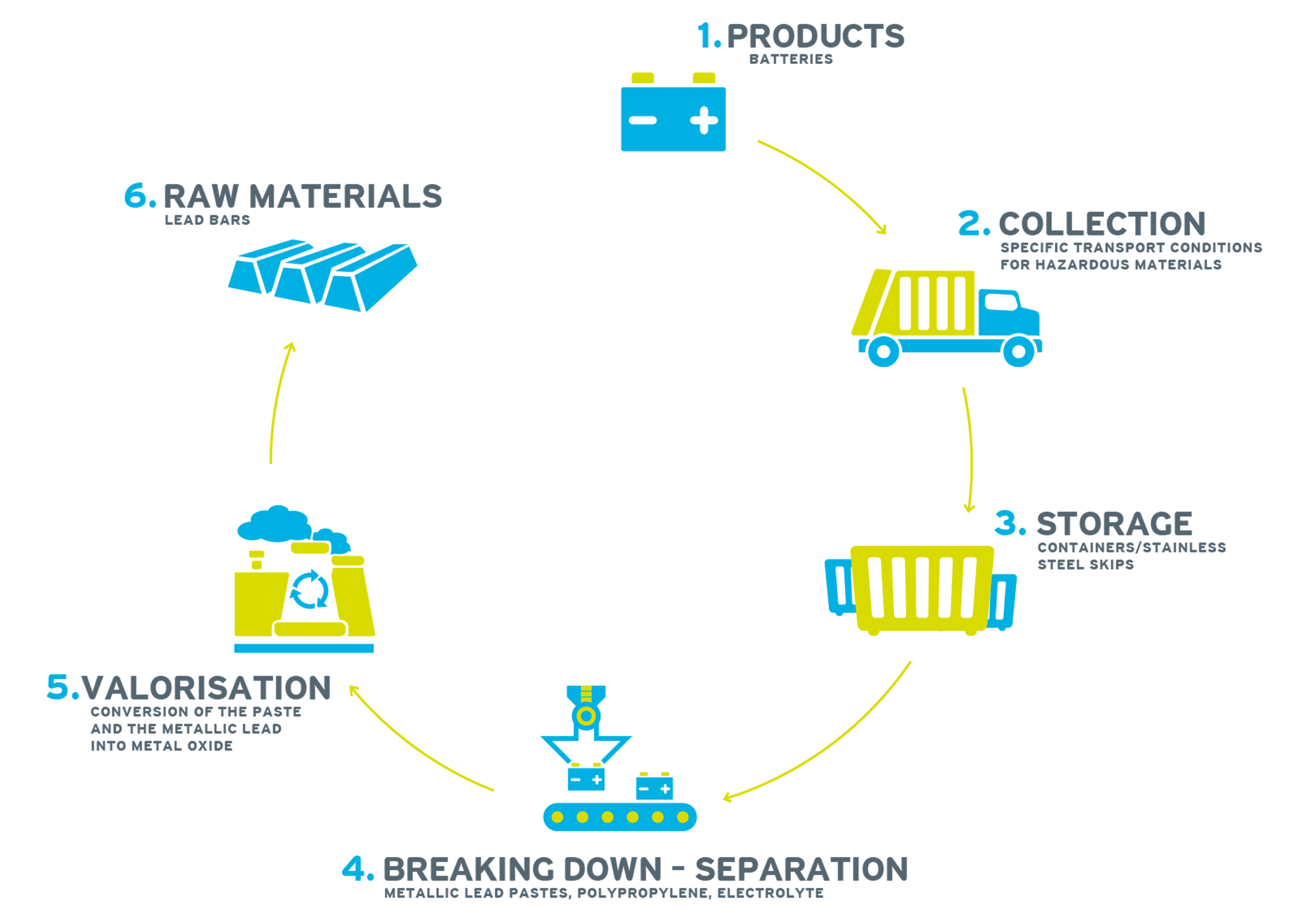

- Handling, decontamination, valorisation and traceability of used lead batteries:

– Processing of acid

– Valorisation of lead and plastic

- Shredding and valorisation of waste metals

- Consolidation and valorisation of Waste Electrical and Electronic Equipment – (WEEE) – processing plant

- Manufacture of fuel for boiler plants from timber packaging

RAW MATERIALS RECOVERY

EPUR, A MAJOR PLAYER IN THE PRODUCTION OF SECONDARY RAW MATERIALS, HELPS BUSINESSES REDUCE THEIR ENVIRONMENTAL IMPACT BY PROVIDING ECONOMICAL, SUSTAINABLE SOLUTIONS.

In waste management, waste valorisation is a set of processes used to recover waste for a different purpose: it can be used to make a new object (recycling), turned into compost or converted into energy (energy recovery from waste).

Valorising waste is better than sending it to landfill.By developing valorisation solutions that supply its customers with quality secondary raw materials, EPUR is setting the standard in renewable resources production and helping its customers become more environmentally friendly while curbing their costs.

The integrated valorisation solutions used in our materials recovery centres are the outcome of a research and development policy focused on our customers’ requirements.

For waste not handled by EPUR, we develop selective partnerships with other processing centres that meet our quality, safety and environmental commitments.

PIONEERING INITIATIVES

RECOVERY OF ENERGY POTENTIAL FROM WASTE

EPUR was a pioneer in the adoption of the Solid Recovered Fuel (SRF) production process, with the first plant installed in 2010 at our Gignac-La-Nerthe site near Marseille. Two new lines are under development in the Rhône and Allier departments of France.

The SRF is produced from ordinary industrial waste, residues from the shredding of Large Domestic Appliances (LDA), wood and bulky waste that could not be reclaimed. They are intended to replace traditional fossil fuels (oil, coal, etc.) to feed energy-intensive industrial plants. This highly specialised treatment enables a very significant reduction in the volume of final waste to be buried in landfill sites.

WHAT DO WE RECYCLE?

WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT

The process used by EPUR combines a number of technologies that allow us to identify and extract all of the plastics from waste electrical and electronic equipment (WEEE), once it has been ground into fractions as small as 1mm. EPUR offers a diverse range of flexible industrial solutions that guarantee standard-setting traceability for decontamination and achieve high levels of recovery.

WOOD

EPUR receives different categories of wood (A, B and C).

It uses a process that identifies, sorts, checks, selects, separates and batches the wood (which is shredded or screened). This gives its customers (boiler plants and board manufacturers) recycled wood materials that meet the predefined specifications and allows them to lower the cost of their raw materials supplies.

PLASTICS

The industrial sorting process developed by EPUR sorts, separates, prepares, repackages and ships the various categories of plastics. EPUR delivers high-quality plastics with a purity rate close to 99%.

INDUSTRIAL BATTERIES

EPUR has facilities capable of collecting and processing every type of battery (Prefectoral Orders on processing).

Starter batteries, industrial traction batteries used as an energy source to power a motor (lift truck, electric car, etc.) and stationary batteries used to carry energy to stand-alone or portable appliances or in the event of an outage.

FERROUS AND NON-FERROUS METALS

EPUR valorises ferrous and non-ferrous metals.

Ferrous metals – or “scrap iron” – is waste from end-of-life metal goods, consumer goods or industrial cuttings. This waste can be endlessly recycled.

Each category of scrap iron is used for a specific purpose and meets physical and chemical specifications. Non-ferrous metals refer to all metals. Non-ferrous metals include two specific categories of metals: precious metals (gold, silver, platinum and palladium) and rare and semi-precious metals (titanium, cobalt, etc.). They are found mainly in motor vehicles, but also in electric cables (copper), buildings (aluminium and zinc), batteries (lead and nickel), household appliances (aluminium and zinc), packaging (aluminium) and coins (nickel).

EPUR issues the certificates of disposal and compliance that are necessary and required by law for all types of waste.